A hand-made harvest

Published 10:36 am Wednesday, December 3, 2014

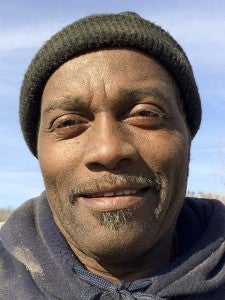

Elisha Barnes estimated he would have 115 to 120 shocks of peanuts when the first part of the work was done in early October. — Stephen H. Cowles | Tidewater News

LITTLE TEXAS

If he’s not already done, Elisha Barnes is soon to complete the harvesting of his peanuts.

What makes the task unique is that this year he chose to do it in what he called “the old-fashioned way.”

With the help of his son, Andre, and a few congregants from his two churches in North Carolina, in early October they loaded the peanuts into shocks.

Gathered around tall wooden stakes — about 115 to 120 — the peanuts were then allowed to ripen with help only from the sun and air.

“The strength of the vines determines the size of the shocks,” he said. “As they dry, the height will shrink. You’ll see the tips of the poles.”

Barnes, who also grows corn and watermelon, along with raising a few hogs and goats, decided to try this method — one of which he remembered his father doing long ago.

Darnell Joyner feeds the peanuts and vines into a 1933 peanut picker that’s powered by the engine of a small farm tractor. — Stephen H. Cowles | Tidewater News

Watching the men using pitchforks to load the peanuts into shocks, it was easy to imagine a brief visit back in time when simple tools and strong labor got results.

He also believes this manual practice will only serve to enhance the quality of the peanuts, which he’ll sell to producers of gourmet peanut and other nut snacks.

“Natural curing gives them a real sweet quality,” Barnes said. “Flash-drying takes that away.”

Jump to eight weeks later, and he’s back in the fields again with Andre, church members and even his brother, Roger. They’re gathered on a sunny weekend for the processing stage, starting with hand-feeding the piles into a 1933 peanut picker that’s connected to the engine of a small tractor, which sputters out a couple of times, but is soon running again.

The thresher quickly separates the peanuts, which drop into large metal buckets. At the same time, the chopped-up vines are blown out into a pile, creating an almost perpetual cloud of dust.

Waiting in a trailer for the peanuts was Larry Warren of Severn, North Carolina.

“My granddad did this,” Warren recalled, adding he hadn’t seen the hand-process since he was a teenager in the late 1960s.

Carl Wynn, a family cousin from Chesapeake who helped to rake up the debris, said he came to see “how it was done 50, 60 years ago.”

Roger said the whole thing moved him and it reaffirmed his love for Southampton County.

Looking around, he said, “We lived this.”

Cracking open a few shells, the peanuts are small in size, but tender to the bite. They taste…natural.

Just as they’re intended.